Grouting Procedure for Repair of Cracks in Concrete Structures:

Procedure of grouting for repair of concrete cracks in structures are:

1. Holes are drilled in structure along cracks and in an around hollow spots.

2.If there are several cracks, holes can be drilled in a staggered manner at 500 to 750mm spacing in both directions covering adequately the area proposed to be grouted. Holes spacing can be altered as per site conditions.

3. G.I. pieces (12 to 20mm dia x 200mm) with one end threaded or PVC nozzles are fixed in the holes with rich cement mortar.

4. All the cracks and annular space around G.I. pipes are sealed with rich cement mortar.

5. All the cracks are cut open to a ‘V’ shaped groove, cleaned & sealed with rich cement mortar.

6. All the grout holes should be sluiced with water using the same equipment a day before grouting as per following sequence; so as to saturate the masonry.

All holes are first plugged with proper wooden plugs or locked in the case of PVC nozzles. The bottom most plug and the two adjacent plugs are removed and water injected in the bottom most hole under pressure.

When the clear water comes out through the adjacent holes the injection of water is stopped and the plugs in the bottom most hole and the one immediately above are restored.

The process of grouting of concrete cracks is repeated with other holes till all the holes are covered. On the day of grouting all the plugs are removed to drain out excess water and restored before commencing grouting.

The same sequence as described above is adopted for injecting the cement grout also. The grout is kept fully stirred/ agitated under pressure throughout the grouting.

The grouting is carried out till refusal and/ or till grout starts flowing from the adjacent hole. A proper record of the quantity of grout injected into every hole should be maintained.

After grouting, curing should be done for14 days. Tell tales are provided for checking the effectiveness of grouting.

Only such quantities of material for preparing grout should be used, as can be used within 15 minutes of its mixing. Grouting equipment must be cleaned thoroughly after use.

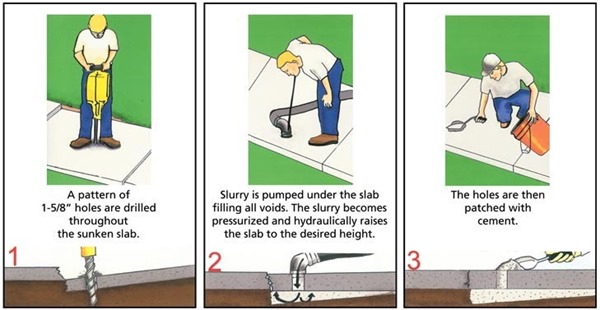

Fig: Grouting Procedure for Concrete Cracks Repair

Precautions during Grouting of Cracks in Concrete :

- During the grouting operation in track or close to it, speed restrictions of stop-dead and proceed at 10 kmph shall be imposed at the site of work and same should be continued for a period of 24 hours.

- The restriction may then be relaxed to non-stop 30 kmph to be continued for a period of another 2-3 days. However, speed restrictions indicated above are only guidelines and appropriate speed restriction at each individual site should be considered.

- Immediately after grouting work, all the grouting equipment including the slurry and mixing drums, pipes, nozzles, etc. should be thoroughly washed so that set cement does not damage the equipment.

- After the work has been completed, it should be inspected thoroughly and should be kept under observation for a period of 6 months to 12 months for its behaviour after grouting.

- In case arch masonry of bridges is grouted to strengthen the structure, some load tests may be carried out in selected cases to satisfy that grouting has helped to reduce the deflection of crown and spread at the springing to within permissible limits.

Thanks for shearing Grouting Procedure for Repair of Cracks in Concrete Structures

ReplyDelete